When Temperatures Drop, Tire Risk Rises

A T-I-R-E-S refresher to help protect drivers, equipment, and passengers in snow and ice season

As winter weather increases across North America, the American Bus Association’s Bus Industry Safety Council (BISC) and Bus Maintenance and Repair Council (BusMARC) are reminding motorcoach operators to tighten tire practices to help reduce blowouts, skids, and weather-related incidents.

The U.S. Department of Transportation’s Federal Motor Carrier Safety Administration (FMCSA) has issued a Regional Emergency Declaration in response to severe winter storms and unusually cold temperatures in the affected states for January 2026. The declaration provides temporary relief from certain federal “hours-of-service” rules (Part 395) for commercial drivers, to help speed the transportation of essential supplies and support the restoration of critical services. Officials say the move is intended to protect public health and safety and address immediate risks to people and property.

A Simple Framework: T-I-R-E-S

BISC and BusMARC recommend using the T-I-R-E-S checklist—based on federal guidance and industry best practices—as a quick way to keep tire safety top of mind during cold, snowy, and icy conditions.

T: Tire inspection

Build tire checks into daily routines. Look for cracking, bulging, cuts, foreign objects, insufficient tread depth, and other damage. Consider adding more tire-specific details to your DVIR process to capture issues consistently and early.

I: Inflation

Pressure management matters year-round, but cold weather adds risk. As temperatures drop, inflation gas can contract, lowering PSI. Verify pressure routinely and use a cold-temperature PSI reference table aligned to your equipment, tire type, and operating conditions.

An example of a cold-temperature PSI table can be found here.

R: Rims

Confirm compatibility and condition. Mismatched tire and rim components can create dangerous failure conditions, including explosive separation and severe equipment damage.

E: Extreme loading

Avoid overloading and underinflation. Either can increase heat buildup and stress, raising the likelihood of tire failure, fire risk, or blowouts—especially under winter operating demands.

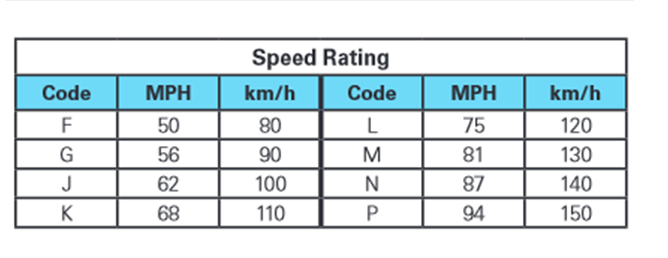

S: Speed

Don’t exceed the tire’s speed rating. Over-speeding reduces service life, accelerates damage, and can lead to failure.

Additional Winter Considerations

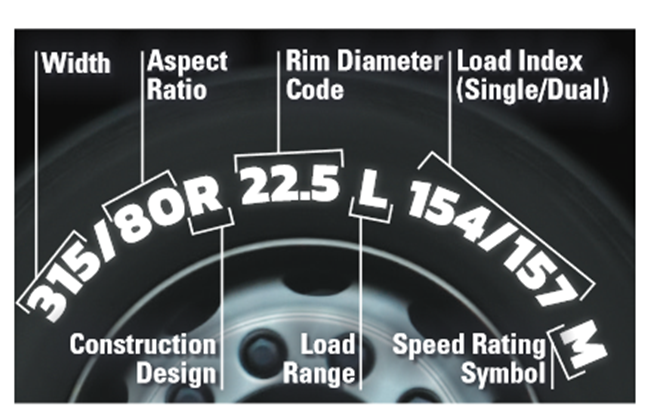

Note that tires designed for extra grip, such as Drive Tires from Bridgestone, Continental, Goodyear, Michelin, and Toyo, may offer benefits in winter operations. BISC and BusMARC encourage operators to understand tire markings so ratings, fit, and application match the duty cycle.

Know Tire Chain Requirements Before You Roll

Chain rules vary by state and can change quickly along winter corridors. Operators should confirm whether chains are required on the route before departure and stay current on applicable restrictions and enforcement conditions.

ABA provides a helpful guide to tire chain laws and operational requirements for several states as a public safety resource.

Monitor FMCSA Emergency Declarations When Conditions Escalate

During state or regional emergencies, FMCSA may coordinate with states and issue emergency declarations that can include targeted relief from certain regulatory requirements to support response activity. Declarations are time-limited, so operators should monitor current postings and verify how they apply to their operations.

Currently, there is one emergency declaration in effect that impacts the motorcoach industry through February 6, 2026. Drivers and operators can check the Federal Motor Carrier Safety Administration website for up-topdate declarations.

Winter tire readiness is more than a maintenance task—it’s a safety commitment. Consistent inspections, proper inflation, and smart operating choices help protect drivers and everyone on the road, reduce strain on vehicles and equipment, and, most importantly, safeguard passengers who trust operators to get them to their destination safely, no matter what the weather brings.